AATEC Lisa Spider: Modular Pick-and-Place Automation for Advanced Tape & Reel

At ProEx, continuous investment in automation is a key part of how we improve quality, throughput, and consistency for our customers. One of the systems helping drive this capability is the AATEC Lisa Spider — a modular, multi-input pick-and-place platform designed for inspection, testing, and tape & reel automation.

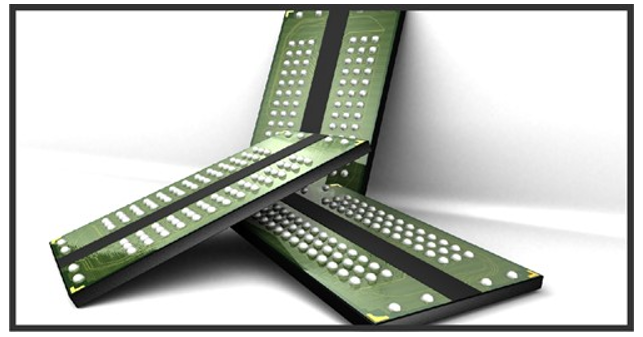

Equipped with an EPSON RS3 robotic arm and advanced 2D/3D vision options, the Lisa Spider delivers output speeds of 2,500–3,500 units per hour with positioning precision of ±0.01 mm. This level of accuracy is critical when handling sensitive semiconductor devices that must meet strict EIA-481, JEDEC, and customer-specific packaging requirements.

The Lisa Spider allows ProEx to:

Automate component transfer from trays, tubes, or bulk input

Integrate inline inspection and optional test verification

Perform precision placement into embossed carrier tape

Increase repeatability and eliminate manual variability

Support high-volume and complex tape & reel requirements

This automation is a core part of how ProEx delivers scalable, high-quality tape & reel services for semiconductor manufacturers and distributors.

How ProEx Supports Offline Device Programming

When it comes to offline device programming, choosing the right partner directly impacts your manufacturing efficiency, security, and cost structure. ProEx provides extensive device support, rapid turn times, and industry-leading quality as an ISO 9001:2015 Certified and ITAR Registered programming house.

Offline programming is not simply a service — it is a manufacturing strategy that removes bottlenecks from SMT lines and improves overall operational flow.

What Is Offline Device Programming?

Offline device programming is a production method where semiconductor devices are:

Programmed outside of the SMT line (manually or automatically)

Verified, inspected, and documented

Marked, repackaged, or tape & reeled as required

Delivered ready for immediate SMT placement

Because programming is removed from the assembly line, manufacturers avoid the slowdowns and risks associated with in-circuit programming.

This approach is widely adopted across:

Medical device manufacturing

Automotive electronics

Aerospace and defense

Government and military applications

Telecommunications and industrial electronics

Benefits of ProEx Offline Programming

Partnering with ProEx provides measurable operational advantages:

Reduced Manufacturing Costs – No capital investment in programmers, sockets, or software updates

Highest Quality Assurance – 100% device and paperwork verification on every order

Maximized SMT Line Capacity – Eliminate programming bottlenecks from production

Secure Data Protection – ITAR workflows, controlled access, and secure file handling

Increased Efficiency – Devices arrive ready for placement

Rapid Turnaround – Built for high-mix, high-volume environments

Reprogramming Capability – Previously programmed devices can be erased and reprocessed

State-of-the-Art Equipment – Latest programming platforms and algorithms

Extensive Device Support – Thousands of socket modules and broad manufacturer coverage

Why Manufacturers Choose ProEx

Outsourcing to ProEx allows your team to focus on core manufacturing while we manage the complexity of device programming.

Decreased Equipment and Repair Costs

We maintain and continuously upgrade a large fleet of programming platforms, sockets, and software so you do not have to.

Wide-Ranging Device Support

Our library of socket modules and programming platforms supports an unmatched range of manufacturer part numbers and media types.

ISO-Certified Quality Systems

Every order follows documented ISO processes, ensuring traceability, repeatability, and accountability.

Deep Industry Expertise

Decades of specialization and direct relationships with programming equipment manufacturers allow us to resolve issues quickly and support complex devices.

Exceptional Responsiveness

Our blend of automation and skilled technicians enables some of the fastest turn times in the industry.

Key Takeaways

Offline programming removes SMT bottlenecks and improves manufacturing flow

ProEx reduces your capital expenses while increasing throughput and quality

Secure, ISO-certified, ITAR-compliant processes protect your data and devices

Broad device support and advanced automation provide unmatched flexibility

Ready to Improve Your Programming Process?

If you are currently programming in-circuit or managing programming internally, there is a more efficient path. ProEx can streamline your workflow, reduce cost, and deliver devices fully prepared for production.

Contact ProEx today for a quote and discover how offline device programming can improve your manufacturing performance.

16 November 2021