How We Program IC Chips:

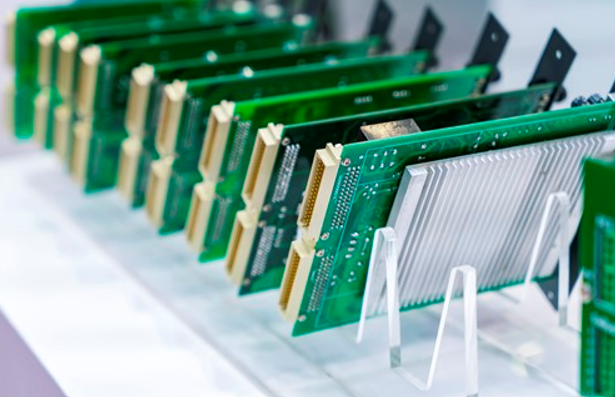

Integrated Circuit (IC) programming is a critical process that directly impacts device performance, reliability, and time-to-market. At ProEx, IC chip programming is more than loading firmware—it is a controlled, secure, and highly repeatable operation designed to meet the demands of modern electronics manufacturing.

This guide walks through how IC chips are programmed at ProEx, from initial preparation to final verification, and explains why offline programming plays a key role in scalable, high-quality production.

Understanding Integrated Circuit (IC) Chips

An Integrated Circuit (IC) is a compact assembly of electronic components—such as transistors, resistors, and capacitors—fabricated onto a semiconductor substrate, most commonly silicon. ICs serve as the functional core of nearly every electronic product, from consumer electronics and automotive systems to medical devices and industrial controls.

Common IC categories include:

Digital ICs – Microcontrollers, logic devices, memory

Analog ICs – Power management, amplifiers, sensors

Mixed-Signal ICs – Combining digital and analog functions

RF ICs – Wireless communication and signal processing

Each IC type presents unique programming, handling, and verification requirements that must be carefully managed to ensure consistent performance.

Selecting the Appropriate Programming Software and Algorithms

Accurate IC programming begins with selecting the correct programming software and device-specific algorithms. These tools define how data is written, verified, and secured within the device.

At ProEx, programming software is:

Matched precisely to the IC manufacturer and device family

Validated to ensure correct memory mapping and data integrity

Controlled to prevent unauthorized access or firmware corruption

This software acts as the command interface between the programmer and the IC, ensuring the device functions exactly as intended in its final application.

Transferring Firmware to the IC Chip

Once the firmware or configuration data is validated, it is transferred to the IC using advanced offline device programmers. This process—often referred to as programming or “burning”—uses controlled electrical signals to write data into the device’s non-volatile memory.

Key elements of this stage include:

Secure handling of customer-supplied firmware

Controlled electrical parameters to protect device integrity

Serialization support for traceability and product tracking

Offline programming ensures that devices are fully programmed before they reach the assembly line, reducing risk and improving production flow.

Verification and Functional Testing

Programming does not end once data is written. Every IC undergoes rigorous verification to confirm that the programming process was completed successfully.

Verification steps may include:

Data read-back and checksum validation

Functional testing against defined specifications

Identification and isolation of any programming anomalies

If an issue is detected, corrective action—such as reprogramming or quarantine—is taken immediately to prevent defective parts from progressing downstream.

The Advantage of Offline IC Programming

Offline IC programming is a cornerstone of ProEx’s value-added services strategy. By programming devices outside of the main production line, manufacturers benefit from:

Increased throughput – Programming does not slow assembly operations

Higher consistency – Dedicated programming environments reduce variability

Improved security – Firmware is handled in controlled, access-restricted systems

Scalability – High-volume automated solutions support growth without disruption

This approach is especially critical for high-mix, high-reliability, and regulated industries.

Precision, Process Control, and Confidence

IC chip programming is a disciplined process that blends software expertise, advanced hardware, and comprehensive quality controls. Whether programming digital, analog, mixed-signal, or RF devices, the goal remains the same: deliver fully programmed, verified, and production-ready components.

Contact ProEx Today

ProEx provides expert IC chip programming services designed to enhance reliability, security, and manufacturing efficiency. From firmware loading and serialization to testing and tape-and-reel packaging, we manage the entire process with precision and care.

If you are ready to streamline your programming workflow and reduce risk, contact ProEx today to schedule a consultation. Trust your IC programming to a partner that delivers accuracy, consistency, and confidence—every device, every time.

July 31, 2023