IC Device Programming FAQs

Your Questions About IC Programming—Answered by the Experts at ProEx

IC device programming is often misunderstood as a simple step in the manufacturing process. In reality, it is a highly controlled, technical procedure that directly impacts product functionality, traceability, security, and production efficiency.

At ProEx, we have provided professional offline IC device programming services for over 20 years, supporting electronics manufacturers, distributors, automotive suppliers, medical device companies, and aerospace/defense contractors. Below are the most common questions we receive about IC programming—and the answers you should know before choosing a programming partner.

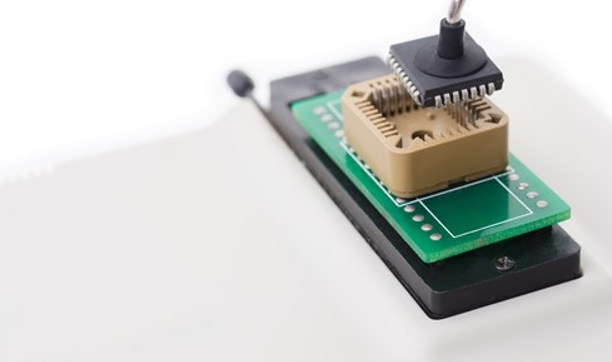

Q: What Is IC Device Programming?

Integrated Circuit (IC) programming is the controlled process of loading firmware, configuration data, security keys, serial numbers, or calibration data into programmable semiconductor devices such as:

Microcontrollers (MCUs)

Flash memory and EEPROM

FPGAs and CPLDs

Secure elements and cryptographic devices

Automotive and industrial controllers

This process ensures the device performs its intended function once installed on a PCB. Proper programming also ensures traceability, revision control, and protection of intellectual property.

Q: What Are the Benefits of Professional IC Programming?

When performed correctly in a dedicated offline programming environment, IC programming provides:

Increased manufacturing throughput

Improved first-pass yield

Reduced SMT line interruptions

Secure firmware provisioning and IP protection

Accurate serialization and traceability

Lower overall manufacturing cost

Faster turnaround times for production

Outsourcing IC programming to a specialist like ProEx removes risk from your production floor while improving consistency and reliability.

Q: How Long Does It Take to Program Each Chip?

Programming time varies significantly based on:

Device type and memory size

Firmware file size

Verification requirements

Security provisioning steps

Typical programming times range from seconds to several minutes per device. Larger flash devices or secure provisioning applications can take longer.

At ProEx, we utilize automated, high-throughput programming platforms from DediProg, Elnec, and other leading manufacturers to optimize speed while maintaining strict verification standards.

Q: What Is the Difference Between Coding and Device Programming?

This is a common point of confusion.

Coding is the act of writing firmware or software (usually performed by design engineers).

Device programming is the act of securely transferring that finalized code into the semiconductor device for production use.

ProEx does not write firmware—we ensure it is programmed accurately, securely, and traceably into every device.

Q: What Programming Languages Are Used for ICs?

IC firmware is commonly written in:

C / C++

Assembly

Python (for higher-level control layers)

HDL languages such as Verilog and VHDL (for FPGA development)

However, these languages are relevant to firmware development—not the programming process itself. ProEx works with the compiled output files (HEX, BIN, ELF, JED, SVF, etc.) and ensures they are correctly provisioned into devices.

Q: What Are Common Issues Associated With Device Programming?

Improper device programming can lead to costly production failures. Common issues include:

Incorrect firmware revision loaded

Improper fuse or configuration bit settings

Device orientation errors during handling

Poor socket contact or improper insertion

Lack of verification after programming

Inadequate traceability or serialization control

Security vulnerabilities during provisioning

Professional programming environments eliminate these risks through automation, verification, and documented process control.

Q: Why Should I Partner With ProEx for Device Programming?

ProEx provides advantages that internal programming or inline programming cannot match:

Dedicated offline high-volume automated programming systems

Same-day First Article processing

Extensive device library support

Secure provisioning and serialization capabilities

Revision control and file management

ISO 9001:2015 quality system

ITAR-compliant workflows

Full traceability and reporting

Competitive pricing at scale

We act as an extension of your manufacturing process—not just a vendor.

Key Takeaways

IC device programming directly impacts product functionality, security, and yield.

Programming time varies based on device and file complexity—not a fixed 1–2 minutes.

Coding is performed by engineers; programming is performed by specialists like ProEx.

Professional offline programming reduces risk, improves throughput, and protects IP.

ProEx provides secure, traceable, and high-volume IC programming for demanding industries.

Need IC Programming Services?

If you are looking for a reliable partner for high-volume, secure, and precise IC device programming, ProEx is ready to help.

Contact us today to discuss your device programming requirements and see how we can streamline your production process.

May 25, 2022