Our Automated High-Volume IC Programming Capabilities

Integrated circuits (ICs) are the foundation of the modern digital economy. From automotive control systems to medical devices and consumer electronics, virtually every advanced product relies on precisely programmed semiconductor devices to function reliably at scale.

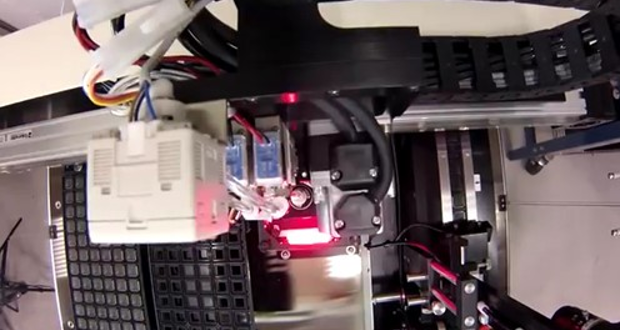

At ProEx, we specialize in automated, high-volume offline IC programming—a secure, cost-effective solution designed to support manufacturers that demand speed, accuracy, and consistency across large production runs.

What Is IC Programming?

Integrated circuit (IC) programming is the process of writing verified software or firmware data into a semiconductor device so it can perform its intended function within a system. This data may control logic, timing, memory, security features, or communication protocols.

An IC programmer transfers this data from validated programming software into the device’s non-volatile memory. Once programmed, the IC acts as the functional “brain” of the end product.

Many ICs function as microcontrollers—compact, self-contained computing systems that manage everything from simple sensors to complex automated equipment. Though physically small, their performance is defined by the accuracy and integrity of the programming process.

How IC Programming Works in Electronics Manufacturing

IC programming begins with customer-supplied code, typically delivered in approved file formats supported by the device manufacturer. This code is written in a programming language appropriate for the device architecture and application.

Key considerations include:

Device compatibility and memory constraints

Programming speed and throughput requirements

Data integrity and verification methods

Long-term reliability and traceability

For large-scale manufacturing, automated programming systems are essential. High-volume IC programming machines ensure:

Consistent results across thousands (or millions) of units

Rapid units-per-hour throughput

Repeatable quality with minimal human intervention

Once programmed, devices are integrated into assemblies ranging from compact consumer products to fully automated industrial systems.

Markets That Rely on IC Chip Programming

Because programmable ICs are highly versatile, they are used across nearly every major technology sector, including:

Primary industries

Automotive electronics and engine control systems

Medical devices and diagnostic equipment

Industrial automation and controls

Consumer electronics

Additional applications

Power tools and heavy machinery

Printers and imaging systems

Gaming systems and toys

Audio equipment and guitar pedals

ProEx supports programming across these markets with cycle times that can range from seconds to extended programming intervals, depending on device complexity and data requirements.

How ProEx Programs IC Chips

ProEx is ISO 9001 certified and ITAR registered, with programming processes designed to meet stringent quality, security, and traceability requirements.

Our IC programming services are performed offline, which delivers several critical advantages:

Reduced overall manufacturing cost

No disruption to customer assembly lines

Maximum throughput via automated systems

Secure handling of sensitive data and devices

The result is a fully programmed, verified IC that integrates seamlessly into your existing production flow.

Key Benefits of Working With ProEx

Cost Efficiency

Eliminates the need for in-house programming labor and equipment

Competitive pricing enabled by high-volume offline programming

Quality and Versatility

Support for a wide range of device types and applications

Automated verification and process controls

Secure, documented workflows

Speed and Responsiveness

Standard turnaround targets of three business days or less

Rush and same-day services available when required

Integrated Services

IC programming paired with tape and reel packaging

Precision handling to support automated pick-and-place assembly

A Holistic, End-to-End Solution

Programmed ICs often require precise packaging to protect device integrity and ensure compatibility with automated assembly equipment. ProEx provides integrated tape and reel services that align directly with programmed device requirements.

Our custom tooling, automated inspection systems, and quality scans help ensure:

Correct orientation and placement

Reduced risk of defects

Consistent, repeatable output

If an issue is detected, it is corrected before shipment, ensuring you receive production-ready components.

Key Takeaways

IC programming is fundamental to modern electronics manufacturing

High-volume automation is essential for consistency, speed, and cost control

Offline programming reduces manufacturing risk and expense

Outsourcing IC programming eliminates the need for in-house infrastructure

ProEx offers integrated programming and tape-and-reel services under one roof

Talk to Our IC Programming Team

IC programming does not need to be complex or risky. With ProEx, the process is secure, scalable, and production-ready.

Our team supports a wide range of programming languages, device families, and volume requirements—backed by rigorous quality controls and fast turnaround times.

Contact us today to request a quote and see how ProEx can support your high-volume IC programming needs with confidence.

September 30, 2022