The Basics of Tape and Reel Services

Precision Packaging for Modern Electronics Manufacturing

The global consumer electronics market exceeds $1 trillion annually and continues to grow at approximately 8% per year. Behind this growth is a highly automated manufacturing ecosystem—where tape and reel packaging plays a critical role in ensuring speed, accuracy, and reliability.

From smartphones and IoT devices to automotive electronics and aerospace systems, tape and reel services enable efficient, high-volume surface-mount assembly. This guide explains the fundamentals of tape and reel packaging, applicable standards, material options, and why partnering with ProEx delivers measurable advantages.

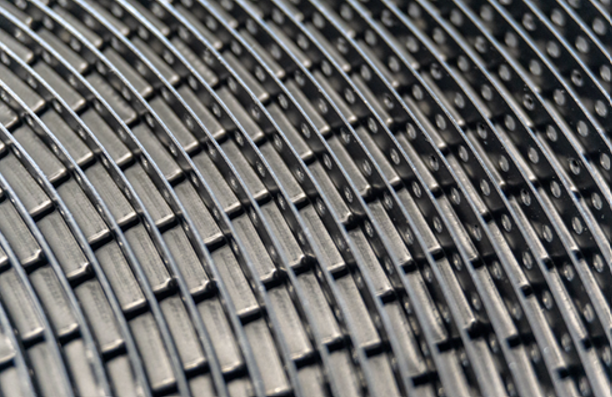

What Is Tape and Reel Packaging?

Tape and reel is an automated packaging process used to prepare electronic components for pick-and-place surface-mount assembly. Each component is:

Precisely placed into an individual pocket within a carrier tape

Sealed with either heat-activated or pressure-sensitive cover tape

Wound onto a reel at controlled tension and spacing

This process ensures components are consistently oriented, protected from contamination, and ready for high-speed assembly.

Carrier Tape Materials and Protection Levels

Carrier tape selection is driven by component size, fragility, and application requirements:

Paper Tape

Ideal for small passive components where minimal mechanical protection is required.Polystyrene (PS)

Offers moderate rigidity and dimensional stability for standard components.Polycarbonate (PC)

Provides maximum protection for delicate, fine-pitch, or high-value devices.

Proper material selection prevents dust, debris, moisture ingress, and mechanical movement—factors that can cause misplacement, reflow defects, or feeder errors during assembly.

Because tape and reel packaging is fully automated, components are never touched by hand, eliminating contamination from oils, dirt, or moisture.

Why Tape and Reel Matters in Assembly

Tape and reel packaging is engineered for precision:

Components are indexed at exact intervals

Orientation is standardized for automated feeders

Reels feed smoothly into placement equipment

The result is highly uniform PCB assemblies, reduced scrap, faster cycle times, and significantly lower defect rates.

Industry Standards and Compliance

Tape and reel packaging must conform to globally recognized standards to ensure compatibility across manufacturing environments.

Key Standards Bodies

Electronics Industries Alliance (EIA)

JEDEC Solid State Technology Association

EIA-481 Tape and Reel Standard

EIA-481 defines recommended dimensions, tolerances, and performance criteria for:

Carrier tapes

Cover tapes

Reels

Taped components

While technically voluntary, EIA-481 compliance is essential for reliable automated handling and is expected by most OEMs and EMS providers.

Procurement documentation typically specifies:

Applicable standard and revision

Reel diameter and component count

Tape quality limits (missing components, splices)

Storage and shipping conditions

Reel weight limitations for feeders and operator safety

Cover Tape Performance Requirements

Cover tape must meet strict mechanical and handling criteria:

Controlled peel force and angle (165°–180°)

Uniform peel speed for feeder compatibility

Secure adhesion during storage and transport

No delamination or residue during unreeling

Pressure-sensitive cover tapes are often selected for higher-speed operations due to their consistent peel characteristics.

Component Orientation Rules

Correct orientation is critical for multi-lead and polarized components. EIA-481 defines standardized orientation rules based on:

Termination location

Component geometry

Orientation features (notches, dots, chamfers)

Tape pocket quadrant

Following these rules ensures compatibility with automated placement systems and eliminates costly rework.

Tape and Reel for Semiconductor Devices

Semiconductors follow the same EIA-481 framework, with additional considerations for:

Electrostatic discharge (ESD) protection

Moisture sensitivity

Vision inspection requirements

Common Tape Widths and Reels

Tape widths: 4 mm to 200 mm

Component pitch: 2 mm and up

Reel sizes: 7” (low volume) and 13” (high volume)

ESD Protection Options

Conductive – allows controlled current flow

Dissipative – safely discharges static

Non-conductive – electrically insulating

Plastic carrier tapes—particularly polystyrene and polycarbonate—are commonly used for semiconductors due to superior dimensional stability.

Alternative Packaging: Tubes and Bulk

For oversized or specialty components, packaging tubes provide a secure alternative:

Components are isolated and protected

Compatible with automated feeding systems

Superior to bulk packaging for damage prevention

Bulk packaging is typically reserved for non-critical handling scenarios.

Applications Across Industries

Tape and reel packaging is essential in:

Consumer electronics (phones, tablets, laptops)

Automotive electronics

Industrial controls

Medical devices

Aerospace and defense systems

Any application requiring precision, speed, and repeatability benefits from tape and reel services.

Why Outsource Tape and Reel to ProEx?

Partnering with ProEx eliminates the need to:

Purchase capital-intensive equipment

Maintain specialized labor

Manage evolving packaging standards

ProEx Advantages

2D and 3D automated vision inspection

EIA-481 and JEDEC compliance

Fast turnaround (standard orders typically ≤3 days)

Expedited services available

Custom tooling for non-standard components

A Custom, End-to-End Solution

ProEx maintains inventory of common carrier tapes and offers custom tooling solutions for unique or challenging components. This flexibility ensures reliable packaging even for unconventional devices.

In addition, ProEx provides semiconductor programming services, allowing components to ship pre-programmed, packaged, and assembly-ready—globally or directly to your manufacturer.

Repeatable job setups enable consistent supply without repeated quoting, helping customers avoid shortages and production delays.

Get Started with Tape and Reel Packaging

Tape and reel packaging is a foundational element of modern electronics manufacturing—improving yield, reducing risk, and accelerating production.

If you need precision packaging, compliance confidence, and fast turnaround, ProEx is ready to support your operation.

Request a quote today and experience tape and reel done right.

31 Jan 2023