Tube vs. Tape and Reel Packaging for Semiconductor Devices

When it comes to packaging semiconductor components, two industry standards dominate: tube (stick magazine) packaging and tape and reel packaging. While both methods protect components during storage and transport, they serve very different purposes on the manufacturing floor.

Understanding the differences between these two formats is critical for manufacturers looking to improve automation efficiency, placement accuracy, throughput, and overall cost control.

This guide explains how each packaging type works, where it fits best, and why tape and reel has become the preferred choice for modern automated assembly environments.

What is Tube (Stick Magazine) Packaging?

Tube packaging—often called stick magazine packaging—was widely adopted in the early days of IC manufacturing. Components are stacked end-to-end inside rigid, anti-static plastic tubes that are capped for transport.

Common Uses for Tube Packaging

Tube packaging is still used today for:

Shipping ICs from semiconductor manufacturers

Low-volume production environments

Manual or semi-automatic assembly processes

Larger components that do not lend themselves well to carrier tape pockets

Advantages of Tube Packaging

Excellent protection during shipment

Stackable for efficient storage

Lower packaging cost at the semiconductor manufacturer level

Simple handling for low-volume or prototype builds

Limitations of Tube Packaging

While effective for transport, tube packaging becomes a bottleneck in automated environments:

Requires manual loading into feeders

Inconsistent component orientation

Increased operator handling

Slower pick-and-place throughput

Higher risk of misfeeds and placement errors

For modern SMT lines designed for speed and precision, tube packaging introduces inefficiencies.

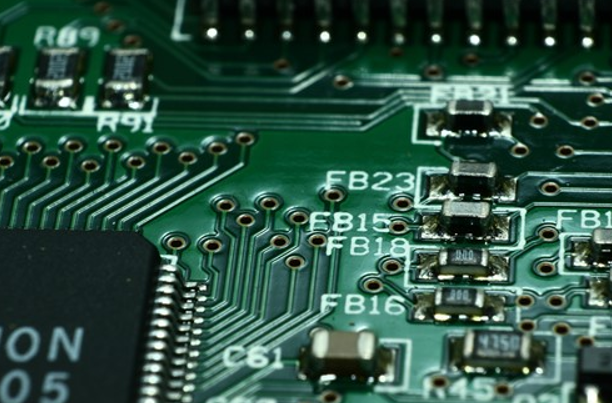

What is Tape and Reel Packaging?

Tape and reel packaging places components into precision-engineered pockets embossed into carrier tape. A cover tape seals the components, and the tape is wound onto a reel for automated feeding directly into pick-and-place machines.

This format is purpose-built for automation, orientation control, and high-volume manufacturing.

Why Tape and Reel is Used in Modern Manufacturing

Tape and reel allows SMT equipment to:

Feed components automatically at high speed

Maintain exact component orientation (per EIA-481)

Reduce operator handling

Prevent jams, flips, and misalignment

Improve placement accuracy and throughput

This is why nearly all high-volume electronics manufacturing today depends on tape and reel packaging.

Industry Standards: EIA-481 and JEDEC

Tape and reel packaging is governed by strict industry standards:

EIA-481 — Defines carrier tape dimensions, pocket design, spacing, and orientation

JEDEC — Defines moisture sensitivity, handling, and protection of semiconductor devices

These standards ensure compatibility across global manufacturing platforms and guarantee reliable automated feeding.

Tube vs. Tape and Reel: Direct Comparison

FeatureTube PackagingTape and Reel PackagingPrimary PurposeSafe transportAutomated manufacturingAutomation FriendlyNoYesComponent Orientation ControlLimitedPrecise (EIA-481)Operator HandlingHighMinimalPlacement SpeedSlowHigh-speedRisk of MisfeedsHigherVery lowBest ForLow volume, shippingHigh volume SMT productionCompatibility with Pick & PlaceLimitedIdeal

Why Many Manufacturers Convert from Tube to Tape and Reel

It is very common for components to arrive from semiconductor manufacturers in tubes, but require conversion to tape and reel before entering SMT production.

This conversion:

Eliminates manual handling at the SMT line

Improves placement reliability

Reduces downtime

Increases overall production efficiency

This is where specialized service providers like ProEx add significant value.

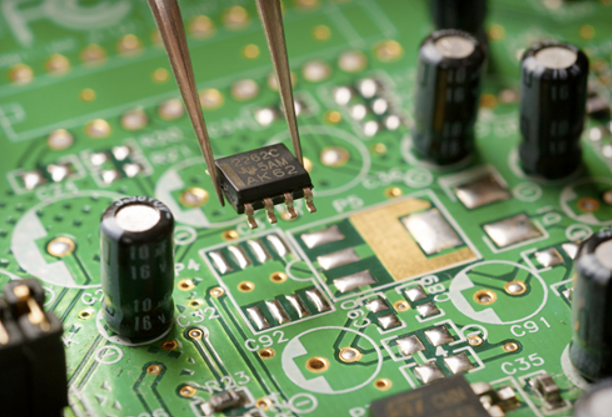

The Role of Offline IC Programming Before Tape and Reel

Before components are placed into tape and reel, many programmable devices require firmware, configuration data, or serialization.

This is performed through offline device programming.

What is a Programmable IC?

Programmable ICs include:

Microcontrollers

EEPROM / Flash memory

CPLDs

FPGAs

Security and authentication devices

These devices must be programmed before reaching the SMT line.

Why Offline Programming is Critical

Offline programming provides:

Verified, tested devices before assembly

Elimination of programming at the SMT line

Reduced cycle time in manufacturing

Full traceability and serialization

Lower overall production cost

At ProEx, devices are programmed, verified, inspected, and then placed directly into tape and reel—ready for automated assembly.

How Long Does IC Programming Take?

Programming time varies by device and file size:

As fast as 1 second

As long as 30 minutes for large or complex devices

This process is completed before tape and reel, ensuring components arrive production-ready.

Key Takeaways

Tube packaging is ideal for transport but inefficient for automation

Tape and reel is designed specifically for high-speed SMT manufacturing

EIA-481 and JEDEC standards govern tape and reel precision

Many manufacturers convert tube components into tape and reel before production

Offline programming before tape and reel significantly improves production efficiency

Why Work with ProEx?

ProEx specializes in:

Converting tube components into tape and reel

Offline device programming

3D inspection and orientation verification

JEDEC / EIA-481 compliant packaging

High-volume automated solutions for SMT manufacturing

Your components arrive programmed, inspected, and ready for the line.

Need Help with Tape and Reel or IC Programming?

If your components arrive in tubes or require programming before assembly, ProEx can streamline your process and eliminate bottlenecks on your SMT line.

Contact ProEx today at 801-569-8500 for a quote.

27 January 2022