How ProEx Is Your One-Stop Shop for Device Programming Services

Device programming is a precise, multi-phase process where verified firmware or data files are securely written to programmable semiconductor devices. While some manufacturers attempt to handle this in-house, the cost, complexity, equipment requirements, staffing, and ongoing support quickly become burdensome.

Outsourcing to a specialized programming house like ProEx removes that burden and accelerates your path from components to finished product.

What Is IC Device Programming?

IC device programming is the process of writing firmware, configuration data, serial numbers, security keys, or calibration files into programmable devices such as:

Microcontrollers (MCUs)

Flash memory and EEPROM

FPGAs and CPLDs

Secure elements and automotive devices

Mixed-signal and specialty ICs

Programming can occur:

For first-time firmware loading

For firmware revisions or updates

For serialization and traceability

For reprogramming previously programmed devices

This process requires precise control of algorithms, socketing, voltage profiles, timing, verification, and data security to ensure 100% reliability.

Industries We Serve

ProEx supports customers across a broad range of industries where programming accuracy and traceability are critical:

Automotive electronics

Medical devices

Aerospace and defense (ITAR controlled)

Industrial controls

Consumer electronics

IoT and connected devices

From pacemakers to automotive ECUs to aerospace assemblies, programmed ICs are the digital foundation of modern technology.

Why Companies Outsource Device Programming

Outsourcing device programming eliminates the operational friction of performing programming during in-circuit test or on the production line.

Pre-programmed devices allow your assembly process to:

Run faster with fewer bottlenecks

Reduce in-circuit programming failures

Improve throughput and first-pass yield

Avoid capital equipment costs and maintenance

Eliminate staffing, training, and floor-space requirements

Most importantly, you receive devices that are fully verified, serialized if required, and ready for immediate SMT placement.

Why Partner with ProEx

1. Capital Equipment, NRE, and Staffing Costs Eliminated

Programming support today is not simple. New semiconductor packages, security features, and manufacturer requirements often demand:

Custom algorithm development

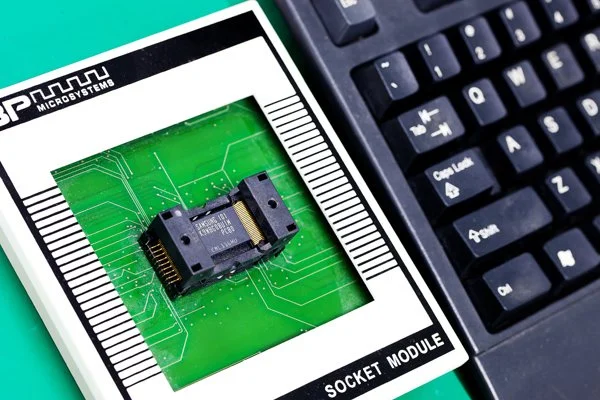

Specialized socket modules ($500–$3,000 each)

Non-recurring engineering (NRE) that can exceed $10,000

Continuous equipment updates and vendor coordination

ProEx has already made these investments across multiple programming platforms. You leverage this infrastructure without absorbing the cost.

2. Unmatched Device and Socket Support

With multiple programming platforms and thousands of socket modules in our library, ProEx supports an extensive range of manufacturer part numbers across device families and package types.

This allows us to quickly onboard new parts and support legacy devices that many in-house operations struggle to maintain.

3. Proven Quality System and Data Security

Programming is only as good as the process behind it.

ProEx operates under a robust quality system and secure environment:

ISO 9001:2015 Certified

ITAR Registered and compliant workflows

Secure handling of customer firmware and data

Verification, traceability, and reporting on every job

Every device is programmed, verified, and documented through controlled procedures designed for high-reliability industries.

4. Decades of Industry Expertise and Vendor Relationships

ProEx maintains strategic relationships with leading programming equipment manufacturers and semiconductor vendors. This allows us to:

Develop support faster

Resolve technical challenges quickly

Stay ahead of evolving device technologies

You benefit from our expertise without needing to build it internally.

5. Responsiveness That Prevents Production Bottlenecks

In-circuit programming often becomes a manufacturing bottleneck. Offline programming at ProEx eliminates this issue entirely.

You can source semiconductors from wherever they are available and send them directly to ProEx for programming, serialization, tape & reel, or custom packaging.

We also specialize in:

Reworking previously programmed parts

Reprogramming due to firmware revisions

Handling mixed inventory situations from the supply chain

These are everyday services at ProEx.

Key Takeaways

IC programming writes critical firmware, data, and security information into semiconductor devices.

Outsourcing eliminates capital costs, staffing, and production bottlenecks.

ProEx provides unmatched device support, quality control, and data security.

Pre-programmed devices arrive ready for immediate SMT assembly.

Reprogramming and rework services solve real supply chain challenges.

ProEx: Your One-Stop Shop for Device Programming

When device programming is outsourced to ProEx, the process becomes simpler, faster, and more reliable for your manufacturing operation.

From secure firmware handling to high-volume automated programming, serialization, and tape & reel services, ProEx delivers a complete solution that gets your products into the hands of users faster.

Choose automated offline device programming from the trusted experts at ProEx.

Contact us today to discuss your programming requirements.

29 July 2022