Tape and Reel FAQs: Everything You Need to Know

The global electronics market continues to expand rapidly, and with that growth comes an increased demand for precision packaging of surface mount components. Efficient packaging is no longer optional—it directly impacts assembly speed, accuracy, yield, and supply-chain reliability.

That is where tape and reel packaging becomes essential.

This FAQ explains how tape and reel works, the standards behind it, and why companies across automotive, medical, aerospace, industrial, and consumer electronics rely on ProEx for high-precision tape and reel services.

Q: What Is Tape and Reel Packaging?

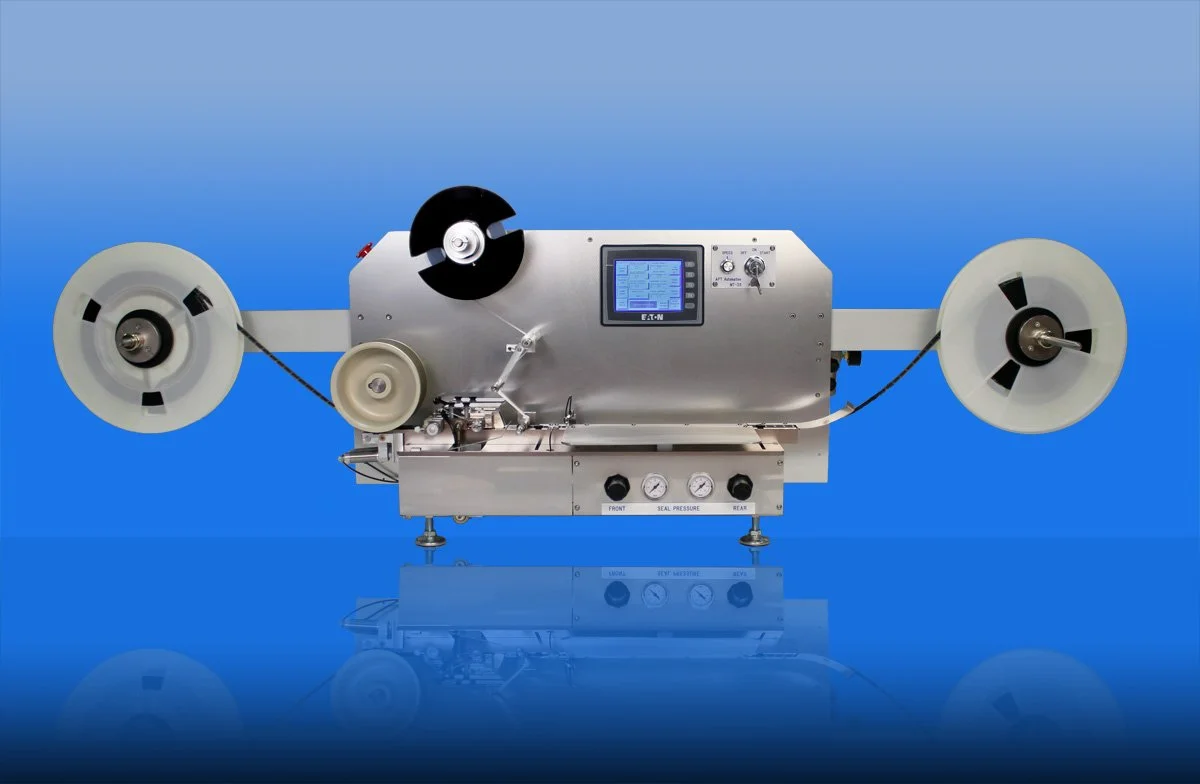

Tape and reel is a method of packaging electronic components into precision-formed pockets in a continuous carrier tape. The components are sealed with cover tape and wound onto a reel for automated delivery into SMT pick-and-place equipment.

This packaging method allows components to be:

Fed directly into automated assembly equipment

Protected from physical damage and ESD exposure

Oriented correctly for high-speed placement

Shipped and stored safely with minimal handling

The result is faster assembly, fewer placement errors, and improved manufacturing throughput.

Q: How Does Tape and Reel Work in Manufacturing?

Tape and reel is designed specifically for automated assembly environments.

As the reel feeds into pick-and-place machines:

The cover tape is peeled back in a controlled manner

Components remain correctly oriented in the pocket

Each part is presented in the exact position required for robotic placement

This consistency is what allows modern SMT lines to run at extremely high speeds with remarkable accuracy.

Q: What Reel Sizes Are Standard?

Industry-standard reel sizes include:

7-inch reels – typically used for smaller quantities and smaller components

13-inch reels – the most common size for production volumes

15-inch reels – used for high-volume runs and larger components

ProEx also supports custom reel configurations for unique customer requirements.

Q: What Types of Components Use Tape and Reel?

Tape and reel is used for nearly all surface mount devices (SMDs), including:

Integrated Circuits (ICs)

Capacitors and resistors

LEDs and sensors

Connectors and small mechanical components

Medical, automotive, aerospace, and industrial electronics components

Any component destined for automated SMT assembly benefits from proper tape and reel packaging.

Q: What Standards Govern Tape and Reel Packaging?

All professional tape and reel services must comply with:

EIA-481 (Electronic Industries Alliance standard for carrier tape)

JEDEC handling and packaging guidelines

These standards define:

Pocket dimensions and tolerances

Component orientation in the tape

Cover tape requirements

Reel dimensions and labeling

At ProEx, every job is built to these standards to ensure compatibility with your assembly equipment.

Q: What Materials Are Used for Carrier Tape?

Carrier tape material is selected based on the size, weight, and fragility of the component.

Paper Carrier Tape

Ideal for small passive components (resistors, capacitors)

Cost-effective for high volumes

Suitable where minimal protection is required

Polystyrene (PS)

Moderate protection

Common for many ICs and thicker components

Affordable and durable

Polycarbonate (PC)

Highest level of protection

Used for delicate, small, or high-value components

Excellent pocket definition for precision feeding

ProEx selects the optimal material based on your specific component and application.

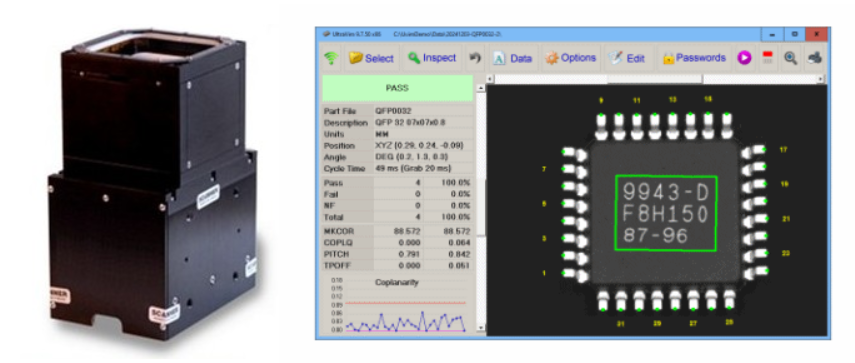

Q: How Does ProEx Ensure Quality During Tape and Reel?

This is where ProEx differentiates from typical tape and reel providers.

Every tape and reel order at ProEx includes:

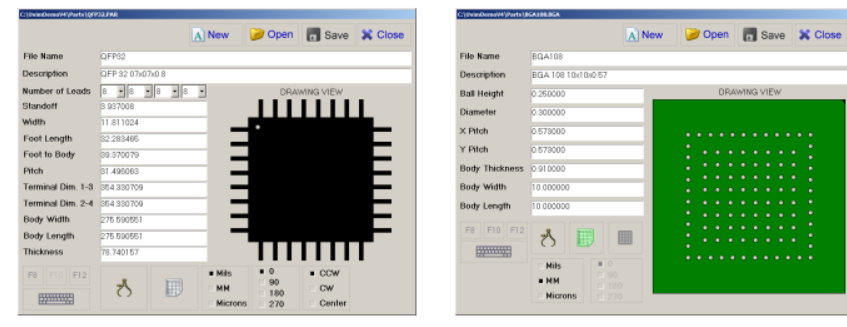

Automated 2D and 3D optical inspection of components before taping

Verification of orientation and pocket fit

Controlled ESD environment

Compliance with EIA-481 and JEDEC standards

Inspection reporting available to customers

This prevents common industry issues such as flipped parts, misalignment, or damaged components reaching your SMT line.

Q: Why Should You Work With ProEx for Tape and Reel?

ProEx is not simply a tape and reel house. We are a value-added semiconductor services provider.

Customers choose ProEx because we offer:

Tape and reel combined with IC device programming

Serialized programming and traceability

Laser marking and labeling

Custom tooling development for unique components

Fast turn times (typically three days or less) with rush options available

Secure handling for medical, automotive, aerospace, and ITAR customers

Most importantly, ProEx delivers components ready to go directly to your SMT line.

Key Takeaways

Tape and reel enables high-speed, high-accuracy SMT assembly.

Packaging must comply with EIA-481 and JEDEC standards.

Carrier tape material matters for component protection and feeding accuracy.

ProEx combines inspection, precision taping, and value-added services in one process.

Ready to Get Started?

ProEx provides some of the most precise, standards-compliant tape and reel services in the United States. With advanced inspection systems, fast turnaround, and integrated programming services, we simplify your supply chain and improve your manufacturing efficiency.

Request a quote today and experience the ProEx difference.

30 June 2022