Tape and Reel for SMD Components: Enhancing Efficiency, Precision, and Supply-Chain Reliability

In modern electronic manufacturing, tape and reel packaging for Surface-Mount Device (SMD) components is not merely a logistics step—it is a critical quality and efficiency driver. Proper tape and reel solutions directly impact automated assembly performance, yield, and long-term component reliability.

ProEx delivers specialized tape and reel services designed to meet the exacting requirements of today’s electronics industry. By combining precision handling, advanced equipment, and deep component expertise, ProEx helps manufacturers protect sensitive devices while optimizing downstream SMT assembly.

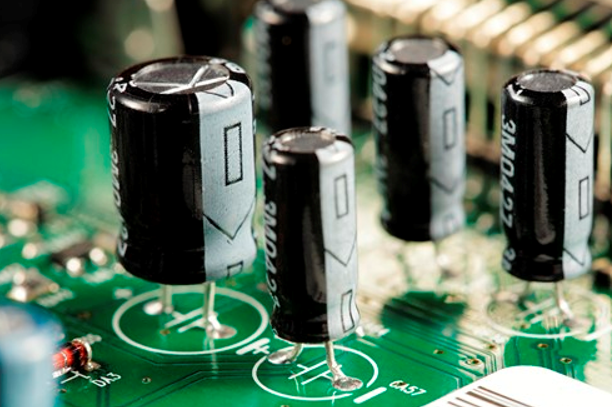

Capacitors and Resistors: The Foundation of SMD Packaging

Capacitors and resistors are among the most widely used SMD components in electronic assemblies. Despite their simplicity, their small size and sensitivity to mechanical stress, moisture, and electrostatic discharge (ESD) demand highly controlled packaging.

ProEx’s tape and reel process ensures:

Accurate placement into properly sized carrier pockets

Secure retention to prevent shifting or lead damage

Consistent orientation for high-speed pick-and-place equipment

This precision minimizes handling damage, reduces feeder errors, and supports stable, repeatable production.

Integrated Circuits (ICs): Complex Devices Require Exacting Control

Integrated Circuits are the functional core of modern electronics—and among the most sensitive components to package. Variations in package type, pin pitch, body thickness, and moisture sensitivity levels (MSL) require a tailored approach.

ProEx provides customized tape and reel solutions for ICs, ensuring:

Proper pocket geometry to prevent lead deformation

ESD-safe materials throughout the process

Compliance with customer and JEDEC packaging requirements

This level of control protects internal structures and ensures ICs arrive production-ready.

LEDs: Protecting Performance and Longevity

Light-Emitting Diodes (LEDs) are widely used in automotive, industrial, consumer, and lighting applications. While efficient and durable in use, LEDs are highly sensitive to pressure, static electricity, and temperature during handling and packaging.

ProEx mitigates these risks by utilizing:

Antistatic tapes and reels

Climate-controlled production environments

Controlled handling processes designed for optoelectronic devices

The result is reduced damage risk, preserved luminous performance, and improved shelf life throughout the supply chain.

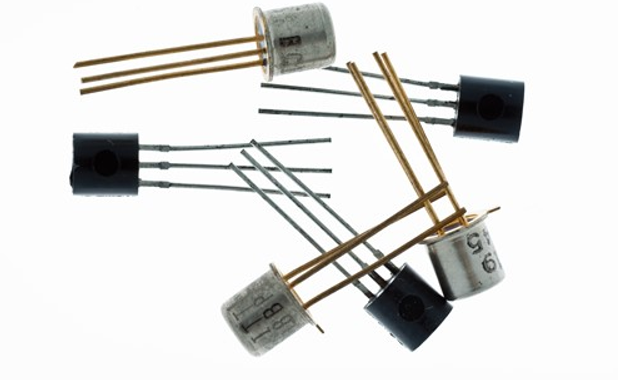

Transistors and Diodes: Small Components with Critical Roles

Transistors and diodes are essential for controlling and directing current flow in nearly every electronic circuit. Because they are often produced and shipped in high volumes, consistent and secure tape and reel packaging is essential.

Outsourcing these components to ProEx provides:

Secure component retention during transport

Reduced risk of bent leads or cracked packages

Improved feeder performance during SMT assembly

This translates directly into higher placement accuracy and faster production cycles.

Connectors and Switches: Precision Drives Reliability

Connectors and switches introduce mechanical complexity into electronic assemblies, often featuring varied pin counts, orientations, and body geometries. Even minor misalignment during packaging can cause major assembly disruptions.

ProEx addresses this challenge with:

Custom carrier tape designs for non-standard geometries

Precise component orientation and alignment

Secure retention to prevent movement during shipment

These controls ensure connectors and switches feed reliably into automated assembly lines without costly interruptions.

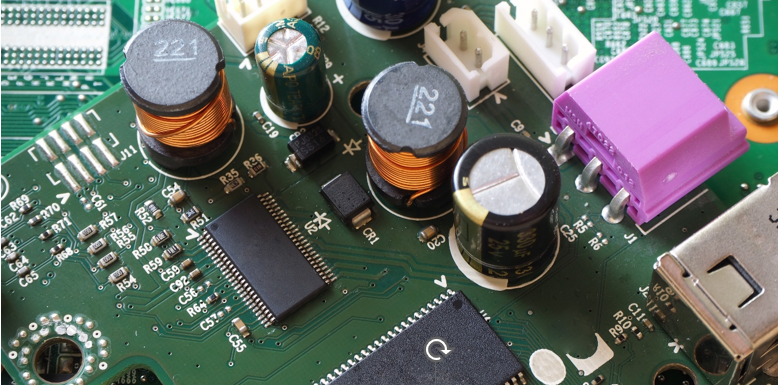

Inductors: Managing Size, Weight, and Stability

Inductors present unique tape and reel challenges due to their larger size, added weight, and structural variation. Improper packaging can lead to cracked cores, shifted windings, or damaged terminations.

ProEx engineers tape and reel solutions specifically for inductors by:

Matching pocket depth and width to component mass

Optimizing reel loading for balance and space efficiency

Ensuring mechanical stability throughout handling and transport

This attention to detail preserves performance characteristics and assembly readiness.

Why Outsource Tape and Reel Packaging to ProEx?

Outsourcing SMD tape and reel packaging to ProEx is a strategic decision that delivers measurable value:

Improved quality and consistency

Reduced internal labor and overhead

Faster SMT setup and fewer line stoppages

Scalable support for low-mix, high-mix, or high-volume programs

ProEx’s value-added services allow manufacturers to focus on design, assembly, and growth—while packaging is handled by specialists who understand both components and production realities.

Sealing Success with ProEx

Precision matters—especially when it comes to SMD component packaging. From capacitors and ICs to LEDs, inductors, and connectors, ProEx delivers reliable, production-ready tape and reel solutions that support quality, efficiency, and long-term supply-chain confidence.

To learn more about ProEx tape and reel services—or integrated offerings such as device programming and value-added semiconductor services—contact ProEx at (801) 569-8500.

January 31, 2024