Tape and Reel Packaging for Medical Device Assembly

In the highly regulated and precision-driven world of medical device assembly, component packaging is far more than a logistical consideration—it is a critical factor in product quality, safety, and manufacturing efficiency. Tape and reel packaging has become an industry standard for handling sensitive electronic components, enabling automation, protecting device integrity, and supporting compliance with strict medical industry requirements.

This article explores the importance of tape and reel packaging for medical device assembly and outlines the tangible benefits it delivers to manufacturers, contract assemblers, and end customers.

What Is Tape and Reel Packaging?

Tape and reel packaging is a standardized method in which individual components are placed into embossed carrier tape pockets, sealed with cover tape, and wound onto a reel. This format is specifically designed for small, delicate, and high-value electronic components that require precise handling.

For medical device manufacturers, tape and reel packaging supports:

Automated pick-and-place assembly

Reduced handling damage

Improved traceability and consistency

Higher throughput and yield

By minimizing manual interaction, tape and reel packaging significantly reduces the risk of contamination, electrostatic discharge (ESD), and human error—critical concerns in medical manufacturing environments.

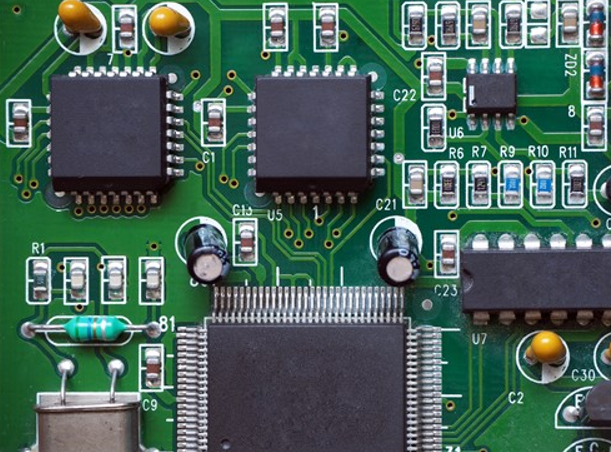

Components Well-Suited for Tape and Reel Packaging

Tape and reel packaging is widely used across medical device electronics due to its versatility and protective design. Common component types include:

Integrated Circuits (ICs) and Microcontrollers

Core processing elements used in diagnostic, monitoring, and therapeutic devices.Passive Components (Resistors, Capacitors, Inductors)

Essential for filtering, voltage regulation, and signal control in medical electronics.LEDs and Optoelectronic Components

Commonly used in imaging systems, indicators, diagnostic tools, and patient monitors.Surface-Mount Connectors (SMD)

Provide reliable internal connections while benefiting from accurate automated placement.Quartz Crystals and Oscillators

Deliver precise timing required in wearables, infusion pumps, and monitoring systems.MEMS Devices

Sensors such as accelerometers, pressure sensors, and gyroscopes used in diagnostics and patient monitoring.RF and Wireless Components

Including antennas and transceivers for connected medical and remote-monitoring devices.Custom and Proprietary Medical Components

Specialized ICs or sensors designed for unique medical applications, often requiring customized tape and reel solutions.

As medical devices continue to grow in complexity, the reliability and consistency provided by tape and reel packaging become increasingly vital.

Enhanced Protection and Efficient Storage

Tape and reel packaging is engineered to protect sensitive components throughout storage, transport, and production. The precisely formed carrier tape pockets restrict movement, reducing the risk of mechanical damage, bent leads, or contamination.

Additional benefits include:

Space-efficient storage and handling

Compatibility with controlled environments

Improved inventory organization and material flow

For medical manufacturers operating in clean, ESD-controlled, or regulated environments, these advantages directly support product quality and compliance.

Streamlining Automated Medical Device Manufacturing

Modern medical device assembly relies heavily on automation. Tape and reel packaging integrates seamlessly with high-speed pick-and-place systems, enabling:

Faster assembly cycles

Reduced labor dependency

Improved placement accuracy

Consistent production outcomes

This efficiency translates into shorter lead times, lower manufacturing costs, and improved scalability—key competitive advantages in the medical device market.

Supporting Medical Industry Standards and Compliance

Medical devices are subject to stringent quality and regulatory standards. Tape and reel packaging supports compliance by enabling:

Controlled handling of sensitive components

Consistent packaging formats

Reduced risk of defects or contamination

Improved traceability through labeling and lot control

When executed by an experienced provider, tape and reel services help manufacturers meet internal quality requirements as well as broader industry and customer expectations.

Customization and Process Flexibility

Not all medical components are the same. One of the greatest strengths of tape and reel services is the ability to customize packaging parameters, including pocket dimensions, orientation, cover tape type, and reel configuration.

Experienced providers such as ProEx tailor tape and reel solutions to match specific component and assembly requirements—ensuring optimal protection, efficiency, and compatibility with downstream processes.

Value-Added Services for Medical Device Manufacturers

Beyond tape and reel packaging, advanced service providers offer integrated value-added services, including:

Device programming

Electrical testing and inspection

Optical and visual inspection

Serialization and traceability support

By consolidating these services, manufacturers can reduce supply-chain complexity, shorten cycle times, and improve overall quality control—an increasingly important advantage in medical device production.

Partner with ProEx for Tape and Reel Services

Tape and reel packaging is a critical enabler of precision, quality, and efficiency in medical device assembly. Choosing the right partner ensures your components are protected, compliant, and production-ready.

ProEx brings deep experience in tape and reel services for the medical device industry, offering customized solutions backed by quality-driven processes and value-added capabilities.

To learn how tape and reel packaging can enhance your medical device assembly operations, contact our experts at 801-569-8500 today.

February 13, 2024