Tape and Reel Packaging Process

Precision, Protection, and Performance for Electronic Components

The tape and reel packaging process is a foundational element of modern electronics manufacturing, ensuring components are protected, traceable, and fully compatible with automated assembly. Below is an optimized overview of how tape and reel packaging safeguards component integrity while enabling speed, accuracy, and compliance throughout the supply chain.

Essential Protection for Automated Assembly

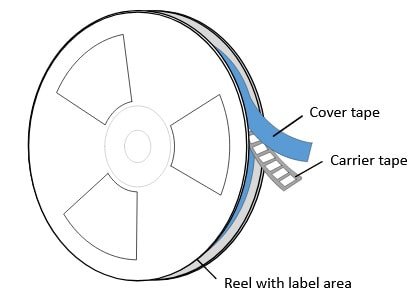

Tape and reel packaging is designed to protect electronic components during storage, transport, and high-speed surface-mount assembly. By securely placing components into precisely formed carrier tape pockets and sealing them with cover tape, this method minimizes physical damage, contamination, and electrostatic risk.

This packaging format is engineered to meet industry standards such as EIA-481 and JEDEC, ensuring seamless compatibility with pick-and-place equipment used across consumer electronics, industrial controls, automotive systems, and medical devices.

Advanced Inspection and Material Selection

Quality begins with verification. Modern tape and reel processes integrate automated inspection and reporting systems that perform both 2D and 3D analysis. Laser-assisted inspection creates highly accurate models of each component, validating orientation, placement, and pocket fit before final sealing.

Carrier tapes are selected based on component geometry, weight, and fragility. Common material options include:

Paper – cost-effective and suitable for lightweight components

Polystyrene – rigid protection for standard SMDs

Polycarbonate – enhanced durability for sensitive or high-value devices

This material flexibility ensures optimal protection without compromising feeder performance.

Customization and Speed

Every component is different, and packaging should reflect that. Custom tooling allows carrier tapes to be engineered for exact component dimensions, ensuring consistent orientation and reliable feeding during assembly.

To support demanding production schedules, tape and reel services are structured for speed and flexibility. Standard orders are typically completed within three business days, with expedited and same-day options available for urgent requirements. All processing is performed in an ESD-controlled, ISO 9001-certified environment to maintain quality and traceability.

Compliance with Packaging Standards

Strict adherence to tape and reel standards is critical to avoiding downstream assembly issues. These standards define requirements for carrier tape dimensions, cover tape performance, and component positioning, all of which directly impact automated placement accuracy. Compliance ensures defect-free feeding, reduced line stoppages, and consistent yield at the SMT line.

Component and Reel Specifications

Tape and reel packaging must meet precise mechanical requirements to function correctly in automated systems. This includes:

Accurate sprocket hole spacing for feeder indexing

Controlled pocket depth and pitch for component stability

Proper reel diameters and weight limits to match feeder capabilities

Meeting these specifications ensures compatibility across a wide range of SMT equipment and manufacturers.

Process Integrity and Material Compatibility

All materials used in the tape and reel process must preserve the electrical and mechanical characteristics of the component. Carrier and cover tapes are selected to withstand storage and transport conditions without introducing contamination, deformation, or degradation. This safeguards component integrity from packaging through final assembly.

Cover Tape Performance Requirements

Cover tape is essential to securing components on the reel while allowing smooth removal during assembly. It must meet defined peel-strength and width specifications and release uniformly—whether the reel is processed manually or through automated feeders. Proper cover tape performance reduces component loss and ensures uninterrupted production.

Ensuring Excellence in Tape and Reel Packaging

Tape and reel packaging is far more than a packaging step—it is a precision process that directly impacts assembly efficiency, product quality, and supply-chain reliability. By combining advanced inspection, material expertise, strict standards compliance, and rapid turnaround, ProEx delivers tape and reel solutions that integrate seamlessly into your manufacturing workflow.

For customized, fast, and dependable tape and reel services, contact ProEx for a quote and ensure your components are packaged to perform from shipment through final assembly.

November 30, 2023