Understanding Component Orientation in Tape and Reel: A Comprehensive Guide

In the world of value-added device programming and tape-and-reel services, component orientation is a foundational requirement for efficient, repeatable, and high-quality electronic manufacturing. Proper orientation goes beyond basic compliance—it directly impacts automation performance, yield, and downstream assembly reliability.

This guide explores why component orientation matters, how industry standards govern it, and how experienced service providers ensure precision at scale.

Why Correct Component Orientation Matters

Correct component orientation in tape and reel packaging is essential for automated pick-and-place systems. Components must be consistently positioned so assembly equipment can identify, pick, and place them without hesitation or error.

When orientation is correct:

Pick-and-place machines operate at optimal speed

Placement errors and rejects are reduced

Line stoppages caused by misfeeds are minimized

Overall throughput and yield improve

In high-volume manufacturing environments, even minor orientation inconsistencies can result in significant downtime and scrap.

Industry Standards and Orientation Rules

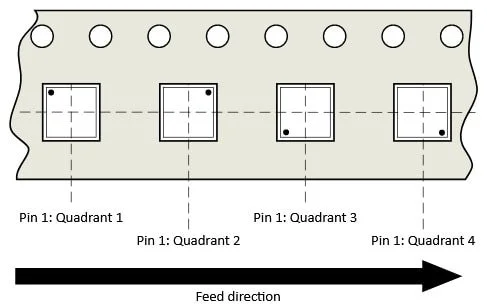

Component orientation is governed by widely adopted industry standards, most notably EIA-481, which defines carrier tape dimensions, pocket geometry, sprocket hole locations, and component orientation relative to the tape’s direction of travel.

Adhering to these standards ensures:

Compatibility across global SMT equipment platforms

Predictable machine setup and feeder alignment

Reduced risk when transitioning products between suppliers or CM sites

Standards compliance is not optional—it is critical to supply chain interoperability and long-term product reliability.

The Role of Carrier Tape and Cover Tape Materials

Material selection plays a decisive role in maintaining proper orientation throughout shipping, handling, and assembly.

Carrier tape considerations include:

Pocket geometry matched to component outline

Dimensional stability to prevent rotation or tilt

ESD-safe materials to protect sensitive devices

Cover tape requirements include:

Controlled peel force for automated removal

Anti-static properties

Secure sealing without component movement

The correct pairing of carrier tape and cover tape ensures components remain fixed in orientation from packaging through final placement.

Custom Orientation and Packaging Solutions

Not all components fit standard assumptions. Irregular shapes, asymmetric leads, polarity-sensitive devices, and custom ICs often require non-standard orientation strategies.

Service providers such as ProEx specialize in:

Custom pocket design and orientation validation

Component-specific orientation requirements

Prototype runs to confirm feeder and placement compatibility

This level of customization ensures even complex or unusual components integrate seamlessly into automated assembly environments.

Impact on Manufacturing Efficiency and Quality

Proper orientation directly contributes to:

Reduced feeder jams and mispicks

Faster machine setup and changeovers

Lower defect rates and rework

More predictable production schedules

Ultimately, orientation accuracy protects both manufacturing efficiency and end-product quality, reinforcing customer confidence and reducing total cost of ownership.

Future Trends in Component Orientation

The future of tape-and-reel orientation is driven by:

Advanced materials with improved dimensional control

Increased automation and in-line vision inspection

Data-driven process optimization and machine learning

As devices become smaller and more complex, precision in orientation will only become more critical. Staying ahead of these trends is essential for maintaining competitive advantage.

The Value of Experience and Expertise

Expertise in component orientation differentiates average service providers from strategic manufacturing partners. Deep knowledge of standards, materials, and assembly equipment enables proactive problem-solving before issues reach the production floor.

Experienced providers ensure components are:

Oriented correctly

Protected properly

Delivered ready for automated assembly

Navigating the Future with Precision in Component Orientation

Correct component orientation in tape and reel packaging is a nuanced yet critical element of modern electronics manufacturing. It requires disciplined adherence to standards, careful material selection, and proven technical expertise.

For manufacturers seeking reliable, standards-compliant, and customized tape-and-reel solutions, partnering with an experienced provider like ProEx ensures precision from packaging through placement.

Contact ProEx today to request a quote or discuss your component orientation requirements.

December 27, 2023