Choosing the Right Device Programming Services: Inline vs Offline

Selecting the right device programming approach is a critical decision that directly affects production efficiency, cost, flexibility, and overall product quality. Manufacturers often weigh inline versus offline programming, assuming inline is the faster or more modern option. In practice, that assumption does not always hold true.

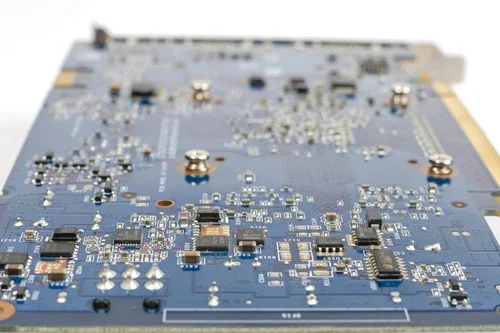

At ProEx, we specialize in offline device programming, particularly for medium- to high-volume programs where scalability, reliability, and adaptability are essential. We also support lower-volume and specialized projects with the same level of precision and care. Understanding the real differences between inline and offline programming will help you choose the approach that best aligns with your operational goals and long-term cost structure.

Why Inline Programming Isn’t Always the Best Fit

Inline device programming programs components directly on the manufacturing line, typically integrated into automated SMT or assembly processes. In very narrow use cases—highly stable products with long production runs—this can appear efficient.

However, inline programming introduces several limitations that often outweigh its perceived benefits:

Higher capital and maintenance costs: Inline systems require significant upfront investment and ongoing maintenance. Any downtime impacts the entire production line, not just programming.

Production bottlenecks: Programming issues, data changes, or rework can halt line throughput, reducing overall efficiency.

Limited flexibility: Inline systems struggle with product changes, firmware updates, mixed builds, or short-term demand shifts.

False assumptions about speed: While inline programming sounds faster in theory, real-world conditions often reveal delays and inefficiencies—especially in high-mix or evolving programs.

For many manufacturers, inline programming becomes a constraint rather than an advantage.

The Advantages of ProEx’s Offline Device Programming Services

Offline programming removes device programming from the production line entirely—allowing it to be performed in a controlled, dedicated environment. This approach delivers measurable advantages across cost, scalability, and operational resilience.

Scalability for Medium- to High-Volume Production

ProEx’s offline programming platforms are designed to scale efficiently across medium- and high-volume programs, while remaining equally effective for smaller or specialized runs. Whether you are programming a single device type or managing a high-mix portfolio, offline programming adapts without disrupting your manufacturing flow.

Cost-Effective and Reliable

Offline programming avoids the heavy capital expense associated with inline systems. By isolating programming from the production line, manufacturers reduce risk, minimize downtime, and achieve more predictable operating costs. ProEx’s systems are built for long-term reliability, delivering consistent quality without inflating overhead.

Flexibility and Adaptability

Offline programming allows devices to be fully programmed, verified, and ready before they ever reach your line. Firmware updates, serialization changes, or customer-specific requirements can be implemented quickly—without stopping production. Inline systems, by contrast, often require line reconfiguration or revalidation for even minor changes.

Offline Programming: Built for Real-World Production Demands

For manufacturers managing complex, high-volume, or high-mix production, offline programming provides the balance of speed, quality, and flexibility that modern operations require. By decoupling programming from assembly, ProEx ensures:

Reduced production risk

Faster response to design or firmware changes

Consistent quality and traceability

Smoother, more predictable manufacturing schedules

Our offline programming infrastructure is fully scalable and designed to support evolving product requirements without introducing inefficiencies or bottlenecks.

Why Manufacturers Choose ProEx

ProEx is a trusted partner for offline device programming because we understand the realities of manufacturing at scale. When you work with ProEx, you gain:

Advanced offline programming technology capable of handling complex and secure programming requirements

Scalable solutions that support both high-volume and high-mix environments

Cost-efficient processes that reduce long-term operational expense

Proven expertise backed by rigorous quality systems and industry best practices

Whether your program demands speed, flexibility, precision, or all three, ProEx delivers programming solutions designed to keep your production moving forward.

Let ProEx Simplify Your Device Programming Strategy

Choosing ProEx means choosing reliability, scalability, and control. Our offline device programming services are built to support your production goals—without the constraints and risks often associated with inline systems.

Contact ProEx today to learn how our offline programming solutions can help you streamline operations, reduce costs, and maintain the highest standards of quality—no matter the size or complexity of your project.