The Advantages of Integrated Circuits (ICs)

Integrated Circuits (ICs) are the foundational building blocks of modern electronics. From smartphones and medical devices to automotive systems and industrial controls, ICs power nearly every digital system we rely on today. Their evolution has reshaped how electronics are designed, manufactured, and deployed.

In this article, we explore the key advantages of integrated circuits—including power efficiency, miniaturization, speed, reliability, and scalability—and explain why ICs remain central to innovation across industries.

The Evolution of Integrated Circuits: A Breakthrough in Semiconductor Technology

The introduction of integrated circuits marked a fundamental shift away from discrete electronic components such as resistors, capacitors, and transistors assembled individually on circuit boards. While essential in early electronics, discrete components were bulky, inefficient, and limited in performance.

By leveraging the unique properties of semiconductor materials, ICs enabled multiple electronic functions to be fabricated onto a single silicon chip. This breakthrough ushered in faster, smaller, more energy-efficient, and highly reliable electronic systems—laying the groundwork for today’s digital economy.

Key Advantages of Integrated Circuits

1. Reduced Power Consumption

One of the most significant advantages of integrated circuits is their low power consumption. Because ICs consolidate multiple components into a single structure with minimal interconnections, they experience far less energy loss than discrete circuits.

This efficiency is critical in today’s electronics landscape, where battery life, thermal management, and sustainability are top priorities—especially in portable devices, automotive electronics, and IoT applications.

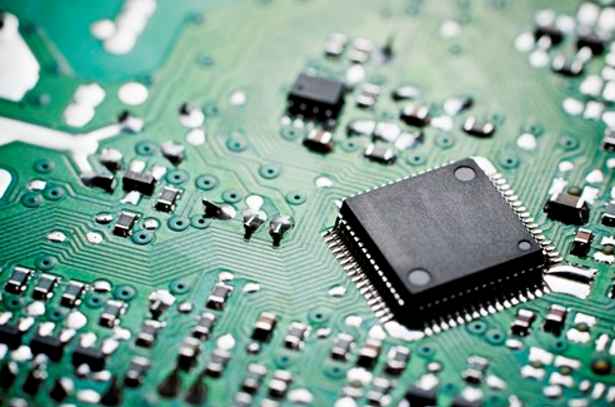

2. Compact Size and Minimal Parasitic Effects

Integrated circuits enable extreme miniaturization. Thousands—or even billions—of components can be embedded within a single chip, dramatically reducing system size and weight. This compact form factor allows manufacturers to design smaller, lighter, and more sophisticated products.

Additionally, ICs significantly reduce parasitic resistance, capacitance, and inductance. Because components are internally connected on silicon rather than through external wiring, signal integrity is improved, noise is reduced, and overall circuit performance is enhanced.

3. High Reliability and Manufacturing Consistency

ICs benefit from highly controlled semiconductor manufacturing processes that deliver exceptional consistency and reliability. By minimizing external interconnections, integrated circuits reduce common failure points such as loose contacts, vibration-related issues, and thermal stress.

Their inherent scalability also enables mass production of identical devices with uniform performance—making ICs ideal for high-volume applications where quality and repeatability are essential.

4. Increased Operating Speed and Performance

Shorter signal paths within ICs allow electrical signals to propagate faster than in discrete circuits. This results in higher operating speeds and improved performance, enabling advanced computing, real-time processing, and high-speed communication systems.

ICs also excel in small-signal applications, delivering accurate amplification and signal processing with minimal distortion—an essential requirement for precision electronics.

5. Simplified Circuit Design and Faster Time to Market

Integrated circuits simplify electronic design by providing standardized, ready-to-use functional blocks. Engineers can select ICs that meet specific application needs rather than designing complex systems from individual components.

This modular approach reduces design complexity, lowers the risk of errors, shortens development cycles, and accelerates time to market—critical advantages in competitive industries.

IC Packaging: Protecting Performance and Longevity

To safeguard these sophisticated devices, integrated circuits are enclosed in protective packaging such as QFNs, BGAs, SOICs, and ceramic flat packs. These packages protect ICs from environmental exposure, mechanical stress, and electrostatic discharge while also aiding in heat dissipation—extending product life and ensuring long-term reliability.

Limitations of Integrated Circuits

Despite their many advantages, ICs do have limitations. Most notably, they are generally not suited for very high-power or high-voltage applications due to thermal and structural constraints. However, advances in power IC design, packaging, and system-level integration continue to push these boundaries.

With proper engineering and application-specific design, many of these limitations can be effectively managed.

The Future of Integrated Circuits

The benefits of integrated circuits far outweigh their constraints. Ongoing innovation in semiconductor materials, fabrication techniques, and packaging technologies continues to drive ICs toward higher performance, lower power consumption, and greater integration.

As electronics become more connected, intelligent, and compact, integrated circuits will remain the driving force behind technological advancement.

The ProEx Advantage

ProEx is at the forefront of integrated circuit enablement, providing expert device programming, verification, and testing services that unlock the full potential of IC technology.

Our capabilities extend beyond programming to include customized handling, inspection, and packaging solutions designed to protect sensitive ICs and ensure flawless performance throughout the supply chain. By combining deep technical expertise with scalable, high-quality processes, ProEx helps manufacturers maximize reliability, efficiency, and product quality.

Programming ICs requires precision, experience, and rigorous process control—and ProEx delivers all three. We help our customers leverage the advantages of integrated circuits while mitigating their limitations, enabling superior electronic products across industries.

Embracing the IC Revolution

Integrated circuits have transformed electronics through their compact size, power efficiency, speed, reliability, and scalability. While not without limitations, they remain indispensable to modern technology and future innovation.

As the industry continues to evolve, ProEx remains committed to delivering world-class device programming and IC services that power the next generation of electronic systems. Contact us today to learn how we can support your IC programming and packaging needs.

June 30, 2023